Digitalizing Factory Assembly Line

We crafted a guidance system that increased output productivity by 30%, revolutionizing manual assembly with enhanced efficiency and accuracy.

Lean Production Management (LPM)

Created in 2019

Challenge

The challenge faced by AdriaDom was the inefficiency and inconsistency in their manual assembly operations. Workers were following different processes, leading to reduced productivity and increased errors. Additionally, the lack of a real-time reporting system made it difficult to identify and resolve issues promptly.

User Group

The user group for the project included the manual assembly workers at AdriaDom. These workers were responsible for carrying out the assembly tasks and required clear instructions to perform their jobs accurately and efficiently.

Solution

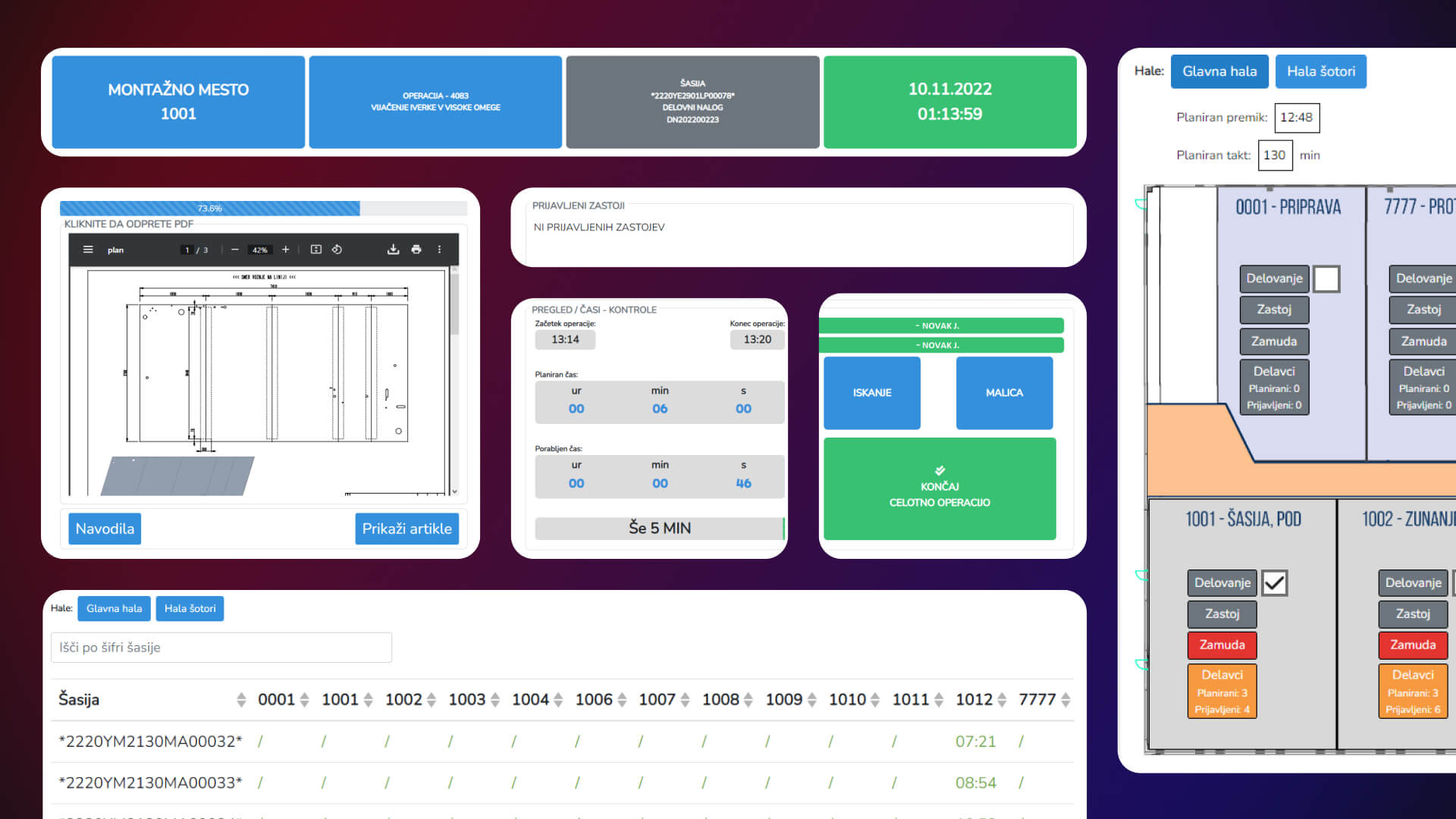

Collaborating with the Faculty of Mechanical Engineering, we implemented the Line Process Management (LPM) system. By leveraging a digital twin, LPM provided digital guidance, standardized processes, and enabled real-time issue reporting. The digital twin allowes us to simulate and optimize workflows in real-time, ensuring efficiency and accuracy.

Results

30% boost in factory productivity, significantly enhancing operational efficiency.

Reporting

Real-time reporting in LPM empowered workers to swiftly report and resolve process jams and errors.

"Higroup has successfully implemented all the required functionalities on time. They go above and beyond to ensure that the products work as intended and are bug-free. They demonstrate a solid grasp of the project, allowing them to deliver unique solutions for the client's complex problems."

ResearcherUniversity of LjubljanaExplore More

Client Success Stories

Frequently Asked Questions

Have some questions? See the most common ones.